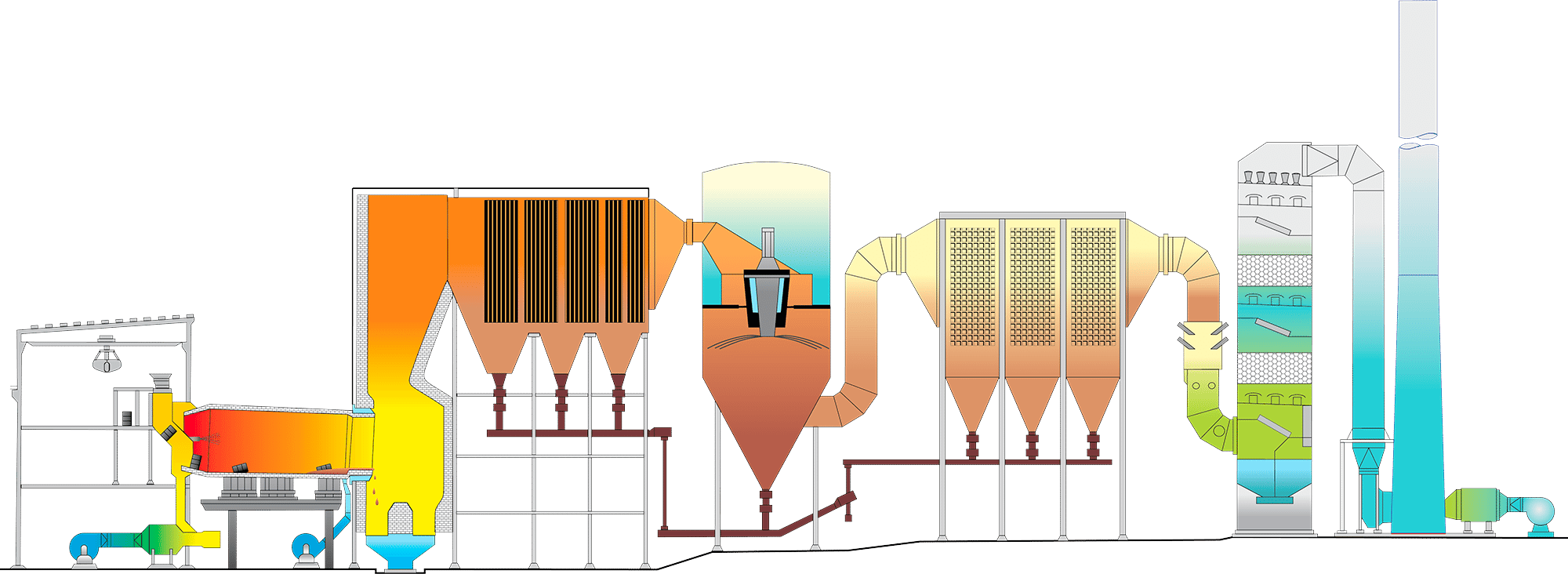

1. Rotary Kiln

The kiln is a refractory brick-lined steel cylinder, measuring approx. 43 feet in length and 16.5 feet in diameter. Pumpable waste is fed into the kiln through pipes called lances. Drums and containers are fed through a double-door entry that leads to a chute. Loose bulk solids are fed into a double-door hopper, which also leads to the feed chute. Same-sized containers, such as packaged consumer commodities, are fed via a skip hoist through the same double-door hopper. It is in the kiln’s interior where Time, Temperature, and Turbulence combine to incinerate hazardous organic compounds. Temperatures range between 1,800°F and 2,200°F as waste moves through the rotating kiln.

2. Secondary Combustion Chamber

The exhaust from incinerated waste flows into the SCC for further combustion. Slag from combustion collects at the bottom of this chamber, where it is removed via a conveyor for shipment to an authorized hazardous waste landfill.

3. Boiler

Combustion gas moves upward through the SCC into the boiler, where it passes through an array of water-filled tubes to generate steam. The steam is used in several of the facility’s processes, including building heat. Blowers that emit high-pressure compressed air prevent the buildup of ash on the tubes.

4. Spray Dryer

Next, the gas streams into this unit, where it is cooled with sprays of water. This cooling process generates salt, which is collected at the bottom of the cone. Like the slag, it is sent offsite to an authorized hazardous waste landfill for disposal. In addition to cooling the gas, the spray dryer completely evaporates water from the wet scrubber [6]. Without the spray dryer, scrubber water would have to be collected and shipped offsite for treatment and disposal.

5. Electrostatic Precipitator

This component features three rows of electrically charged fences. As combustion gas moves through these fences, particulate material adheres to the metal bars. Electronically timed hammers on top of the unit knock the particles downward into the spray dryer hopper.

6. Four-Stage Wet Scrubber

Acid gasses and submicron-sized particles are removed in this unit, which is made up of packed scrubbing beds and spray jets. Water used in this process is recycled to the spray dryer, where it is evaporated.

7. Induced-Draft Fan

This fan maintains negative air pressure throughout the entire system, ensuring that air is always drawn inward.

8. Re-Heater

Before the cleaned and scrubbed gas is emitted, its temperature is raised to ~190°F, improving the elevation of the plume and the effectiveness of the in-stack monitoring equipment.

9. Stack

The water vapor and gas are emitted through a single stack.

10. Activated Carbon

Activated carbon is injected at several places in the emissions-control system to capture trace organic compounds. The carbon is then removed by the electrostatic precipitator and the scrubber.

Wastestream descriptions may include: Corrosive liquids and solids; Explosives (1.3, 1.4, 1.5, 1.6 on a case-by-case basis); Reactives; Flammable liquids and solids; Organic peroxides and oxidizers (liquids and solids); Pesticides, herbicides, and insecticides; Aerosols and fuels; Lab packs and loose packs; Miscellaneous hazardous and non-hazardous waste; Mixed infectious hazardous waste; Consumer commodities and product recalls.

Only when we are certain about what we’re dealing with can we manage it properly. But before we accept any hazardous waste, we ask customers to provide a profile of the material along with a physical sample. We then make sure the sample is analyzed thoroughly for conformity with the profile. Only when the results are proven to correspond with both the profile and the regulatory requirements will we schedule the waste for shipment. On arrival at our facility, we will then pull a sample of the shipment for additional tests. After acceptance, the waste is placed in the appropriate processing or storage area.

Our facility is designed specifically to the very highest safety and environmental standards. It includes a spill-containment network to prevent stormwater incursions. And any vapors that come from material handling, sampling, and storage are captured for safe combustion.

For Customers Needing to Dispose of Waste Safely—the Heat Is On

That’s why, when it comes to safe, reliable waste disposal, we have an industry-leading incinerator facility.

For larger organizations, there’s just a 90-day window to safely dispose of waste—hazardous and non-hazardous. Time frames are very important. And equally important is the peace of mind that comes from knowing disposal will be carried out to the highest standards of safety, compliance, and technological requirements. Thermal treatment—high technology-based incineration—provides proven disposal benefits, including the destruction of hazardous organic compounds and the reduction in the volume of hazardous wastes going to landfills. And Arcwood’s rigorously analytical approach means every step of the disposal process is transparent and fully accountable.

SAFE and COMPLIANT, ALWAYS is our leading value. Generators will find this commitment in everything we do when they rely on us to meet their environmental needs. For materials that require incineration, our employees, service, and process are second to none.

– Chris Pherson, President, Arcwood Incineration Services